Wednesday, January 31, 2024

Change One Thing

Mylar

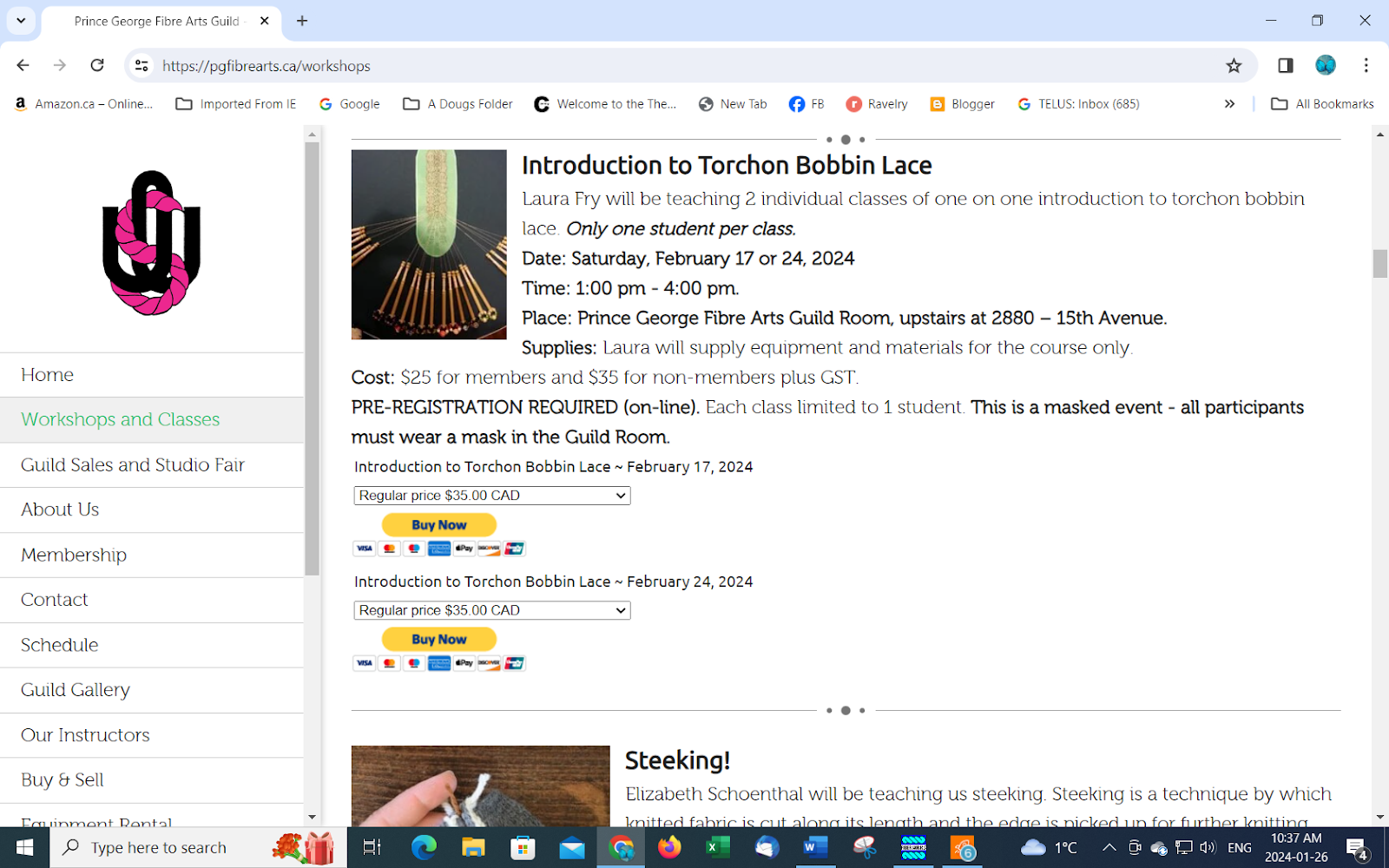

Nancy asked how I used the mylar thread in my lace. This is a bookmark I made a while ago (a really long while ago!)

The shiny thread in this one isn't the same as the hologram thread I'm using in the current bookmark, but shows how I use it. Normally I will wind one of the cotton threads with the mylar as part of my working threads, not as a separate gimp.

This bookmark isn't one of my best. I'm not terribly happy with how I used the mylar. It does act to 'frame' the spiders, though, so it's not terrible. But it does divide the 'heart' motif at the edges so that you lose the shape.

For the current bookmark, the mylar is much thinner and not textured, as such. I placed those pairs one pair inside the edge threads and I'm not all that pleased with that placement, either. I had intended to make it the outside pair, then changed my mind as I was setting up the pillow.

It's the same pricking as this one, and since I don't have the instructions for how to make it, I'm winging it. And making a bit of a hash with it.

I'm also finding it hard to see. My eyesight has deteriorated over the years and it's harder to see the fine threads and the fine lines/dots of the pricking. Let's just say I've unmade nearly as much of the current bookmark as I've made!

This design is probably (likely!) a skill level or two above what I should have tried next. But I had bobbins already wound with the red 2/20 merc. cotton and it seemed like A Good Idea at the time.

The above bookmark was 'mounted' by using a trifold piece of heavier paper, a 'slot' was cut into the paper just the width of the narrow point of the book mark, then the bookmark was carefully inserted into the paper. The paper had a 'cover' (back and front) printed on it and I offered some for sale. I did sell a few, but mostly I gave them as gifts.

The bookmarks I am making now are practice pieces and will be given as gifts. My goal is to make 'ornaments' for an xmas tree and donate them to the guild's tree, decorated co-operatively with some of the other tenants of the arts studio building. The Festival of the Trees is a fund-raiser for the local hospital and generally quite popular. It is one way to give back to our community, and I'm happy to make some small items that can decorate our tree.

Bobbin lace is a kind of weaving where you build your loom as you create your textile. Warps can (and do!) turn into wefts. You can twist, cross, knot, and generally make the threads go 'off grid' in order to create motifs. You can work in the round, a square, or long lengths. Or make shapes. I've done a bit of designing, usually tape lace, some simple Torchon items, but I'm hardly an expert. But I am pleasantly surprised at how much my hands 'remember'. I think I can, at least, show people who are interested the basics. And then let them loose to carry on if they wish.

Tuesday, January 30, 2024

Preparations

I knew that bobbin lace was time consuming, I've done it before. But I'd forgotten just how much time it takes to get everything ready for the bobbin fwipping to actually begin! Not unlike weaving on a loom, honestly.

(I'd like to say I really hate Windows 11 and how when I scan things they get filed in Google docs, or some obscure place I can't find them readily, or make them play nicely with Word.)

After fighting with the scanner the other day and again yesterday, I did finally manage to get the next pricking I wanted to do scanned and enlarged slightly (so I can SEE what I'm doing) and printed out. The one nice thing about using the scanner and printer is that I get nice crisp prickings to work from.

Last night after dinner I rummaged and decided to use up more of the red thread already wound on a bunch of my bobbins. That meant I only had to actually wind half as many bobbins, because so many already had more than enough thread on them. I simply pulled off as much as I needed for the other half of the pair and wound that.

This design required 20 pairs (40 bobbins). It's a step up in skill level from the last two bookmarks, and since I can't find the book it's from, I had to carefully study the pricking, think about the structure of lace, about what I've done previously, and then interpret how to achieve what was supposed to happen in the textile.

Then while I began winding I thought about how to do something to 'bling' the bookmark up. I have some special 'fancy' mylar thread and in the end decided to wind the two outside pairs with red and the mylar to make a nice outline for the bookmark.

By then, however, I was pretty much 'done' with winding bobbins, so I left the mess on the dining room table and will do those last two pairs today.

Just noticed the mylar spool of thread is in the photo, right 'behind' the tube of red mercerized cotton. I think they call it hologram yarn or something. (Label is long gone.) It's shiny and tends to reflect different colours. I've used it before in lace projects and it works well. And, while it's 'expensive' such a little is needed, I don't mind spending the money. :)

We are having 'weird' weather - again. This time it's 'too warm'. Last night we had a big wind storm blow through, which I somehow managed to sleep through. This morning we have lovely bright sun, which is a welcome sight after all the dreary grey days we've been having.

But winter is not over (I hope). With the recent sudden warm temps the little snow we had has melted off and if things don't change soon, the drought we've been having is going to continue. And if it does, this summer is going to be really really bad - for wildfires, but also for agriculture. Expect food prices to go up (again) as supplies begin to dwindle. Because it isn't just here that is experiencing drought - it is all down the west coast. And California produces a lot of the food we rely on, which may become scarce if we don't get some relief from the drought conditions.

Here in BC we rely on hydro electric sources for our power and we may discover what extreme heat and lack of electricity to run a/c feels like.

At least there are more people recognizing that climate change is a 'thing'. I just wish they would stop telling me how to adapt to it, and focus on fixing it. If they can terraform Mars for people to live on, I'm pretty sure they could 'fix' climate change here on earth. Just saying...

Monday, January 29, 2024

Learning Curve

is curvy...

I'm glad I chose this bookmark design to begin with. It's easy, just two 'stitches' and I'm using 2/20 merc. cotton so the threads are big enough I can see to do it. :)

Today I will look for a different bookmark design, something with another stitch in it. There won't be a lot of time in the 'taster' sessions, but I would like to have each person go away with at least a sampler (to learn the basics) and then maybe a small item. I have a couple of student 'pillows' I could send them home with and let them finish, then meet with them again to do the finishing part, which can be a bit tricky for a new lace maker.

I didn't do anything 'fancy' for these, I just wanted to remember how to make lace.

Yes, I undid and redid each bookmark - the first one more times than the second. So it felt like I was making progress. Learning how to recognize a mistake, then take it back and fix it, is a very important part of lace making. As it is with any textile (or other?) craft.

These will get a pressing, then be inserted into a plastic 'sleeve'. In my deep dive in the studio collecting all of the lace stuff in one place, I actually found the stack of sleeves I bought from my English lace making friend. When I use these up, I'm not sure where to get more. Guess I'll have to figure that out when I get there.

In the meantime, I have begun weaving the linen weft towels. It's looking good, so far, and I'm pleased that I can use up another yarn in my stash. The linen is a bit fiddly to work with, even after steeping in the humidor for a few days. But the relative humidity in the house is below 30% so some unruliness is only to be expected. The end result appears like it will be well worth the extra effort.

Yesterday I was able to read through (most of) the latest iteration of A Thread Runs Through It. It's looking good. We are on track for the scheduled launch date, and that pleases me no end.

I still have 'I donwanna' tasks on my task list and I know I need to tackle those - soon. At least I managed to get a few of them done during my light duty days.

The lace stash still needs to be organized and stored...somewhere. But in the meantime I will keep picking away at this and see what I can manage.

Sunday, January 28, 2024

Impostor Syndrome

Got the next bookmark started. Since I'm working with 'fat' yarns, I had to figure out how to scan the pricking (design), then enlarge it. Harder than I expected given the computer now converts scans to Google documents, which then needed to be converted to something I could insert into a Word document and enlarge.

I'm not a patient person, especially when I remember how easy doing this sort of thing used to be, and quite honestly I don't remember how I managed to get it done, therefore have no idea how to do it again. However, success once implies success can be achieved again, and it made a very clear design to work from, so I'm quite pleased with myself.

OTOH, I had another bump into impostor syndrome this morning.

I remember the very first time I saw myself (in a chat group) referred to as an 'expert'. It was so shocking to me to be called such that I quite literally cringed. (I physically 'shrank' into myself, ducking my head, thinking, no, no, I'm not an 'expert' - 'experts' know everything and I certainly do not!)

That is Imposter Syndrome.

It is the inner voices telling you that you are not 'enough'. You don't know enough. You aren't 'good enough'.

It is something I have had to deal with all of my life, and here I am now, in my 70s, and today saw myself referred to as a 'professor' and immediately thought to myself that oh no, I'm not a Professor!!!

Teacher, sure. Professor? Um. Professors have 'qualifications' and I...do not. At least not anything academe would recognize as such.

OTOH, I did teach college level classes for a number of years as an adjunct teacher.

Impostor Syndrome is something that I have had to deal with for decades. Entering the field of weaving *because* I could see that one person could never know it ALL, which was actually one of the big attractions for me, no matter how much I learned, I was well aware of how much *more* there was TO learn.

As I took the master level program from Guild of Canadian Weavers and began to get a better handle on how threads made cloth, I still knew there was SO much more TO learn.

To discover myself being referred to as an 'expert' was not comfortable. It felt like I was claiming something I was not.

Even after I achieved the master level, I still felt very uncomfortable to be described as an 'expert'. And I still do NOT know it 'all'. That doesn't mean I don't know anything, because I do. I know a lot, actually. (Take that Impostor Syndrome!)

This is one of the topics I have written about for the next book A Thread Runs Through It*. Because the longer I have been in this field, the more people I know, the more I understand just how many of us wrestle with Impostor Syndrome.

It can be a very lonely struggle. Impostor Syndrome means that a person feels like a fraud, in some ways. And to admit that they don't feel like an expert feels like a weakness. Or a confession.

I have had to embrace the fact that I do not know 'everything' there is to know about taking thread and turning it into cloth. To *celebrate* that there is still so much more TO learn. To never be afraid to make a mistake, and admit that I have. And then try to 'fix' it and grow/learn from making said mistake.

Our society gets so tied up in 'perfection' without acknowledging the long journey of learning that brings us to 'good', never mind 'perfect'. Always seeing that 'imperfect' journey as a flaw, when in fact it is the very essence of learning. Growing.

Writing about my particular journey was cathartic. And I hope that anyone else also struggling with Impostor Syndrome will manage to wrestle their naysayer back into the dark and keep growing, keep learning.

Thank you, previous student who called me 'professor'. It means a lot to be held in such a position in your life, in your journey. And it allowed me, once again, to tell my inner critic to go away. Not everyone will be interested in my journey as a professional weaver/designer/teacher/author. But maybe my journey will help them to understand that they are not alone. And do what they need to achieve their dreams, their goals.

*nearing completion. Launch date deadline is Feb. 14. Stay tuned.

Saturday, January 27, 2024

Insomnia

Could not get to sleep last night and in the end gave up trying for a while and decided to distract myself by working on the bobbin lace bookmark on my pillow.

It isn't 'pretty' but it's done. It could use a good pressing, although there are a few issues with tension (I'm out of practice) and the yarn is slippery and thicker than 'usual' (it was a practice piece). But overall, I figured it out, even though it took a few runs at it.

This style of lace is called Torchon and is about the simplest of the bobbin laces. Since I hadn't touched bobbins for at least 5 years, I was actually surprised that I remembered (or my hands did) what to do. Mostly.

It was also a good reminder to pay attention to the pattern (pricking) instead of just assuming!

Once that was done I stripped the bobbins from this and the previous project (a dud, but good practice to get me going). In the bag with the bookmark pillow there was a package of bobbins already wound with yarn, so next I'll see about doing a project with that. It's 2/20 mercerized cotton and I used to use that a lot for lace making. It's thicker than sewing thread, but still thin enough that it makes good bookmarks and such. And I need more practice before I do my lace 'taster' sessions.

Since I no longer have a photocopy machine I'll have to scan and print out the prickings to work from, but I think I can 'size' them by pasting into Word, then enlarging the 'picture'. Something to try later.

In the meantime, I did manage a few hours of sleep (eventually) so I'm going to go weave on the loom. I think I can finish the navy 2/16 today, then cut off and re-tie.

Once the navy cotton is done, I'll switch to some of the linen I 'discovered' in November. But that linen is thicker than 2/16 cotton, so I'll weave a header, check what the yarn wants to beaten in at, then decide on a treadling and generate the length. Since the linen is heavier, I will be using a finer linen (limited in quantity) to weave the hems, so I have to program the treadling to warn me when I need to switch to the hem weft, then weave in a cut line (which I can do by changing the tie up, OR inserting a contrasting colour). There is probably more than enough of the linen to finish this warp, so the rest of it will get used up on the next warp. And then one more yarn will be used up.

I won't use the heavier linen for bobbin lace because it is a singles, but the finer linen thread could be used for lace as it is plied. I will see what is left at the end.

Another grey dreary day. It is raining. In January. The roads are sheets of ice. The snowpack is melting away - and there was too little to begin with. It seems the current drought conditions are going to continue in the 'north' for the coming year.

Things, they are a-changing...

Friday, January 26, 2024

Still Weaving

but on a much smaller scale!

After sorting through my bobbin lace supplies over the past few days and getting one-on-one 'classes' set up for next month, I quite literally dusted off one of my pillows and set about trying to get this tiny star finished. It is barely larger than a dollar coin and quite frankly I could not remember how it was supposed to be made so I made my best guess and forged onwards.

It is now ready to be sewn up (tail to beginning), then I'll braid a hanging cord and take it off the pillow.

It was with a sigh of relief that I sat down and actually remembered (or my hands did) how to do the cloth stitch (ie plain weave) the star is mostly made with. I will have to see if I can find the book I took the design out of and re-read the instructions.

One thing is abundantly clear - I will have to enlarge designs so that I can actually see what I'm doing. My eyes just aren't as good as they were and such tiny threads and pins packed so closely together make it hard to see the pricking (the design I'm following).

I had a bit of a bobbin lace 'stash' to begin with, then when mom died, I kept all her sewing thread (mostly quilting thread) because those bits of spools held enough to do small items in bobbin lace. Then, as I 'finished' weaving with the 2/20 mercerized cotton, I figured those nearly empty tubes could also be used for bobbin lace. I used to use 2/20 merc cotton all the time and it worked well. I will never make bobbin lace with anything finer than those threads now. But I understand what it takes to use really fine yarns and appreciate the exquisite nature of such delicate textiles.

Since I am not interested in committing to large projects, I will stick with tiny things like this star. Even enlarged, it will still be 'tiny' and will only take a few hours to make.

My local fibre arts guild is looking at joining forces with a couple other guilds to make a tree for the Festival of Trees, so that is a perfect excuse to make small items like this star, or the birds I was going to try making again.

There are two 'classes' (tasters, just to see if anyone is interested in continuing) booked for February, and I would be willing to do at least one more. These are one-on-one, a lace pillow and bobbins will be supplied, and I have 3 'kits' consisting of pillow, bobbins and a book on lace that I can sell to anyone interested.

I know there are lace makers in town, but none currently involved in the Fibre Arts Guild, so it would be nice to grow a few more. Then we could set up a lace making group.

In the meantime, I need to practice my skills and get comfortable reading prickings and explaining how the bobbins move to create cloth.

Bobbin lace is weaving, but where your warps can turn into wefts, where plain weave can morph into knots, twists, and turns, creating the 'holes' in the cloth that make 'lace'.

Bobbin lace is dated to around the 1400s, generally accepted to have started in Italy, then spreading across Europe.

There are elements of sprang, netting and weaving involved, and of course we all know those gigantic lace 'collars' from paintings from the 1500s. Yards and yards of extremely fine threads made into those iconic (and very stiff) collars.

Now, most bobbin lace makers do smaller items - window dangles, bookmarks, decorative edgings to adorn collars and cuffs. In the 1980s lace makers began to break out of the traditional and use colour and now there are many lace makers working with colour to great effect.

For me, though, it is another way of 'weaving' that is less physical and may provide a way to keep playing with threads if weaving becomes too...much...for my body.

For now, however, it would just be nice to grow a group of people also interested in this craft.

Register here if interested. (Scroll down to get to the lace listing)

Thursday, January 25, 2024

Crystal Ball

The news went out yesterday - Olds College is cancelling Fibre Week and phasing out the diploma programs - Master Weaver and Master Spinner.

To my knowledge this was the only college level course in Canada that directly addressed learning these crafts to 'master' levels. (There used to be a textile program at Capilano College in Vancouver, but not to the technical aspects the Olds program did - that I am aware of.)

This is a huge blow to the spinning/weaving community.

Fibre Week had a great vendor hall, which allowed Canadian vendors to meet and greet customers in person, a fleece judging event which allowed shepherds to showcase their best fibre/fleece, workshops in various aspects of textiles, a 'keynote' address, fashion show, the chance to meet other fibre folk and network. Plus, of course, the five day master classes. (They say that folk currently taking the first levels will be able to finish, but I suspect that will depend on how many people actually enroll to take a particular level?)

What will replace it? WILL it be 'replaced'?

What is left?

I posted on my FB page for people to list Canadian events (because my focus right now is what is available to Canadians - there are still a large number of events in the US) and there has been a great response with people listing events they know about.

Mostly my concern is how people who want to learn more, dive deeper than, a weekend workshop will manage that.

Given the rise in on-line teaching, there are some things available. And, while on-line isn't as 'good' as in person, until something else comes along, we are not bereft of options!

Personally I am doing 1 and 2 hour presentations via zoom. My focus for the past few years (certainly since teaching for the Olds program) has been on the deep dive down the rabbit warrens of weaving. So what you get from me is not the basic bare bones 'how to weave' but more about the physics and subtleties of the craft.

Frankly I began with a deep dive into wet finishing - still not understood by so many - and how essential it is to understand the process. (Magic in the Water)

From there I launched into the subtle changes that the weaver can effect by understanding the relationship between their materials, their equipment, and how to work more ergonomically - which generally means more efficiently as wear and tear on one's body is reduced by using less effort for greater output. (The Intentional Weaver)

Last year I went even further, detailing things that there was rarely time to look at during the Olds class. An already jam-packed course just couldn't expand very far beyond the assigned curriculum. (Stories from the Matrix)

And now? Another book is in the pipeline. My editor says she should have a 'final' copy to examine next week. (A Thread Runs Through It)

Handwoven, Spin Off and Ply magazines are now doing fibre events. Handwoven, of course, has online workshops based on the DVDs that were produced (including mine).

The Ontario Guild has a teaching program - a blend of in person and remote learning, as I understand it. The Guild of Canadian Weavers has a testing program (I was the 27th person to achieve the master certificate. The first was Mary Black - yes, that Mary Black.)

There are regional events - from Fibres West in BC to several in the Maritimes, and stops in between. Even my small town now has a fibre event with vendors, but no classes (that I'm aware of).

In addition to School of Sweet Georgia, where I now have four classes available, Jane Stafford presents a thorough and methodical approach to learning about weaving. The Handweaving Academy is building their course content. And Franquemont University has spinning and Andean weaving (etc) content.

Just this morning I received a request to do a remote presentation for a guild on the other coast. If anyone is interested in what my topics are, they are listed on my website.

I may be raising my fees this year - I've been told by several groups my prices are too low for what I am providing(!)

My books are available here

My next book, due out in February will be available on my ko-fi shop It will be pdf only which will allow me to keep the price lower than offering it via blurb.

And, of course, this blog, where I look at various aspects of weaving (and life).

In the meantime, there are still regional conferences. The next ANWG will be in WA, next year. There are other gatherings in other US regions, and there are gatherings in other provinces.

The Olds program was initially developed and sponsored by the Handweavers, Spinners and Dyers of Alberta. At this point it is impossible to know if this program will go away or come back in a different format.

But in the meantime, we can still carry on, keeping this craft alive and teaching newcomers. When I started weaving there were maybe a dozen or so 'standard' weaving texts. Now we have dozens of titles, some of them very specific, some more general.

It will be up to us, the hand weaving/spinning community to be creative and come up with something appropriate for the community now, in the 21st century.

Tuesday, January 23, 2024

Iterations

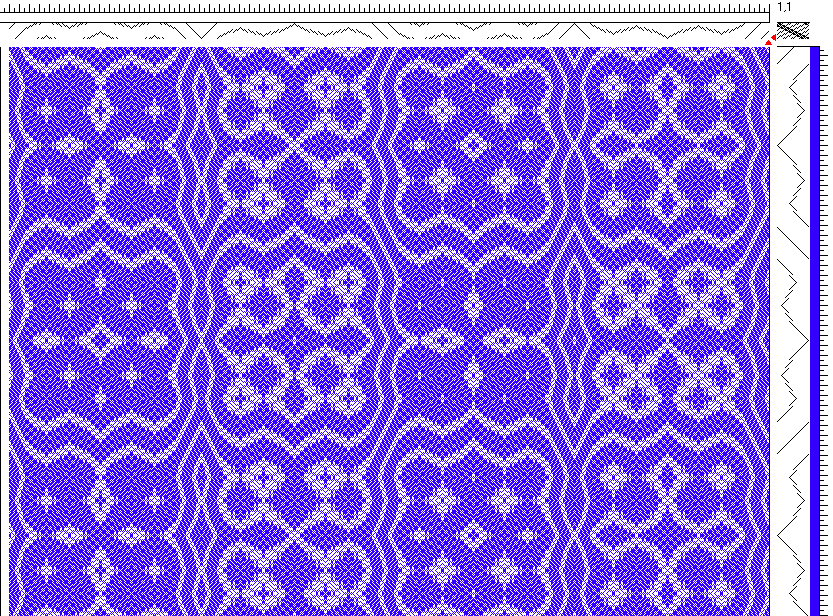

After posting about how long it may take to develop a draft, lo, gaze upon this one - which took 6 iterations and about 6 plus hours to get to this stage. (It may have been longer, I spent nearly two hours just on this one.)

The design is quadruples and isn't actually how I wanted it, but as close as I could come before my patience ran out. Even so, I was just about to dump the whole file, but after taking a long break, went back and suddenly saw how I could make it work. Even though it wasn't exactly what I wanted.

It's not 'perfect' - the squares aren't exactly 'square' but I did what I set out to do and finally made something I want to weave to see how it turns out after wet finishing.

This is what creative people do. They don't pull designs like this out of the hat (usually) on the first 'go'. This is where I am at after working with this weave structure for about 20 months. It took that long to explore the potential, weave some simple designs, watch how the designs developed as I tried this, then that, kept looking at how the drafts were formed, pushing the design lines this way, then that.

This draft is #6 in the 'tile' series, but there were plenty of rejects in between 1 through 6.

I am nearing the end of this series. The current warp, then 3 more, and I should be 'done' using up the majority of my 2/16 cotton yarns. I may return to doing towels in 2/16 at some point, but I also have a deep stash of rayons (bamboo, Tencel, bog standard rayons) and the only real use for those will be scarves and/or shawls. Since I'm out of shawls, I will do a warp or several, and try to use up some of my rayon stash.

While I am still struggling to carry on, being off the opioids means my brain is functioning better and I'm feeling...restless...and wanting to deal with some of the chaos my life is currently in. A house that is too 'dirty', too cluttered, even for my low standards and desperately needs to be dealt with.

Spinning and bobbin lace, languishing for far too long, and *also* with deep stashes. I'm just about ready to put the puzzles away and drag out my bobbin lace stuff. I will be offering one-on-one tasters for anyone interested in bobbin lace, which means I have to refresh my skills in that area.

Really understanding how a weave structure works and being able to manipulate the threads to create something 'new' generally comes after a great deal of thought and then good old fashioned work, with plenty of 'rejects'.

In our current society, people tend to want 'instant gratification', when sometimes it takes a whole lot of brain squeezing and thought. And to be willing to say nope, that isn't what I want, how do I get to where I want to be from where I am? IOW, accepting 'failure' and trying something different, something new, something based on what has gone before.

This is how working in a series actually functions. I don't expect to make something truly 'original' my first 'go' or even my 10th, as this series shows clearly. I think this is warp 15 or 16 in the series, and it is only now beginning to be something more than working with the obvious twill lines and becoming something unique.

Am I saying no one else in the history of weaving has done this before? Absolutely not. But it is unique to me, and I have had to really work my brain to get to this point.

Elizabeth Zimmerman would say that she had 'un-vented' something when she came up with something new/unique in her experience.

I will claim that I have 'un-vented' this design in this weave structure.

If anyone is interested in how this weave structure works, I wrote about it and included skeleton drafts and tie-ups in Stories from the Matrix. Because you can't copyright a draft, it is just a set of potentials. What you do with it will be something new and unique to you.

And that's what this is all about, to me.

(still two signed copies of Stories in my ko-fi shop)

Monday, January 22, 2024

How Long Does It Take?

This is the warp going into the loom at the moment. It was inspired by 'snake skin' but the warp colour is a combination of two blues (peacock and bleu moyen from Brassard) so I'm calling it 'chameleon'. The first weft will be navy with a slightly purplish cast, from Borgs (I think - it's been in my stash for a while. A looooong while.)

Once that yarn is used up, the rest of the warp will be woven with a fine natural linen from Brassard. I think Brassard still carries it, but I'm trying really hard to use up what I have, and I have 4 tubes of the stuff so probably more than enough to finish this warp, maybe do more on the next.

As part of my 'new' reality, I have been paying a lot more attention to how long it takes me to do the various tasks involved in weaving. Since I can no longer weave for as long, or as frequently, it has become more important for me to pay attention to how long I do things for and not push myself beyond my ability to do the things I love.

My body has sustained injuries over the years, and while most of those injuries were not caused by weaving, they are not helped by weaving more than I can tolerate.

My new 'normal' is to work in the studio for no longer than 45 minutes, twice a day. Three times if one of those sessions is 'light' duty (ie pressing, or inspection/repair, etc.)

Since I've just finished beaming the next warp and begun threading, my awareness of the numbers is pretty fresh.

I begin by coming up with a design I think might look good and it generally takes about 30 to 60 minutes to work through the designing of the draft. More if I'm working out a new-to-me weave structure. I then put it 'away' for a while, then go back and look at it again. If I still like it, it may take another 15 or 20 minutes to make sure I'm happy with the transitions from one part of the design to the next, make sure it's 'balanced' if I want it symmetrical, and then generate the treadling, which may take another 20-30 minutes as I tweak the draft to 'fit' a tea towel size. So, about 2 hours (or more) for each design in the designing phase.

I beam sectionally, making a warp 24" in the width, 24 yards (approximately) long, which will produce about 18 to 20 towels, depending on the repeat length. Larger motifs may be longer than designs with a shorter repeat. Rather than cut a motif in half, or worse, thirds, I will either cut back one full repeat and do more repeats for the hem area, or weave the towels a bit longer.

Once I have the bobbin rack set up, I have been doing 5 warps of the same colour combination so I don't have to keep setting the bobbin rack up each time, which saves me some time. Setting up the tension box and then beaming the warp takes about 90 minutes with a longish break halfway through. This includes transferring the bouts to the long stick I use to bring all the sections up and over the back beam so I can reach them during threading.

The current towels are only 32 epi (not 36, which I was using for the mercerized cotton for weft) and it takes about 3 hours to thread the 760 ends (again broken into 45 or so minute sessions with long 'rest' periods between). Generally those 4 sessions are spread out over 2 days.

Sleying will take maybe an hour, depending on how smoothly things go. I may find threading errors that need to be fixed. Sleying tends to be done in one session since the posture/position isn't terribly awkward. If I feel up to it, I may tie on right away, or I may leave it and come back later.

Tying onto the apron might take 10 minutes, then I need to get the treadling sequence into the laptop and bobbins wound. Bobbin winding may be done here and there, for example if I'm waiting for the press to heat up so I can press the towels ready for pressing.

Weaving takes about one hour per towel. On a good day I might be able to weave 900 to 1000 picks in 45 minutes. So a warp that yields 20 towels will take about 20 hours to weave off. I will cut off after about 6 or 7 towels, re-tie and then keep going.

Then when the towels are cut off the loom, they get cut apart and serged, then inspected and repaired. The repairing part can take quite a long time depending on how many things need to be fixed, then a load will go into the washing machine (I might do all 18 or 20 towels at once, or I may do 14) and dryer.

Once they have been run through the washer and dryer (hottest wash water available, cold water rinse, with a double rinse, then into the dryer until damp), they sit overnight to 'steep' and make sure they are evenly damp. Then press. Each towel takes about 4 to 5 minutes to press and then hang on the drying rack, then grab the next towel and get it into the press. They are allowed to dry overnight, then they get hemmed. I can do 2 towels per hour, so about 15 minutes to trim, pin, and sew by hand.

Then, at last, the final press which takes about 2 minutes. Hang to dry (I spritz them with water for their final press) and then the next day they get neatly folded and set onto the shelves where they will live until they get tagged/priced and delivered to the guild for sale. Since I make my own care labels and affix the appropriate label to the hang tag, then use a stem gun to attach the label to the towel, that also takes time (and money because I have to purchase the custom hang tags and plastic stems, and then the care labels to the tag, then add a price tag when selling locally.)

If I offer them on ko-fi, I need to get photos (as accurate in colour as I can manage - not always an easy task!) then the description written up, the photo added and posted to my ko-fi shop.

So let's add that all up, shall we?

Prep time will get divvied up over the number of towels I make. Let's say 19 towels as an 'average'.

Prep time (approximately - it may vary) is about 400 minutes or about 6.66 hours. Divide that by 19 and prep time per towel is 21 minutes. That's before I ever pick up the shuttle.

Then about 60 minutes to weave each towel

'Finishing' adds up to around 30 minutes.

Marketing will add more time.

21 + 60 + 30 + 5 = 116 minutes (edited to correct the time)

Approximately.

Materials for a towel are about 5 ounces for 2/16 cotton. About 1000 yards for warp and about the same for weft for an estimation of 2000 yards per towel. As per the Brassard 2023 price list, 8 oz of 2/16 cotton comes to $8.50 (plus taxes, plus shipping). Yarn for a single towel is therefore about $5.50. More if I'm using linen for weft, but let's just consider cotton for the moment.

I am currently charging $30 per towel when I sell locally, but $40 per towel, which has a shipping charge included when via ko-fi. Considering shipping is currently more like $20 per packet, that means I'm actually 'losing' money when I sell on ko-fi. Unless someone buys two towels, and then the $10 shipping levy for each towel actually covers the actual shipping I pay at the post office. Doesn't cover the cost of the padded envelopes, the cost of the mailing labels, shipping tape (because the labels scrape off if they aren't stuck down with clear shipping tape. Nor does it cover the cost of my labour to do the preparation for shipping, nor the cost of gas to drive to the post office, nor my time standing in line etc.

People tell me I'm fast. I prefer to use the term 'efficient'. I try to not waste my time because once I've spent the coin of my time I can never get it back again. So there are times when I will sacrifice yarn at the end of the warp. I don't like playing 'yarn chicken' so if I'm not sure I can get another towel out of the warp, I may toss several ounces of warp yarn into my yarn recycle bucket.

If I run into problems, I may cut off, fix the problem, and toss the beginning part away - again into my cloth recycle box to be used for 'rags'.

Part of the reason all of this is top of mind right now is because of my next book. A Thread Runs Through it is a memoir - a closer look to what my life looked like as a professional weaver/teacher/author.

I have had to 'justify' my prices over the years because people ask 'how long did it take to make a towel'. Normally I don't go into all of that detail above because that isn't really what they are asking. What they want is for me to justify the price I am asking. Most of them are not interested in the detailed breakdown I've just done.

My prices also reflect my knowledge and skill. So while it may 'only' take me about 2 hours to make a towel, that level of production is based on nearly 50 years of honing my skills, learning my craft, and creating unique and above all, functional, textiles. Nor have I included 'overhead' - all the things that cost money regardless of any production happening. Electricity to run the loom, press, bobbin winder, the lights. Maintenance on equipment - just this month $110 to service the serger. But also any repairs/maintenance the loom requires. Separate rider for studio insurance (because no insurance company in the world would cover the loss of my studio equipment/yarn/inventory on a 'regular' home insurance policy.) The heat. Water. No, I'm no longer in 'business', but after 40 plus years of being a home based business, I'm well aware of the over head costs.

No, I will not give a discount to random strangers.

But I will, at times, gift my work to people I know will appreciate them. Or I will give textiles to my health care providers. Because they are, right now, the only thing keeping me functional enough to actually get to the loom.

Why do I share all this? Because there are still people who are not valuing their work and selling their textiles for far too little. Perhaps they have never bothered to keep track of their investment in time *and money*. Or they don't have to worry about finances that way I did.

Some people who *are* trying to earn an income weaving get very stressed about the people 'giving' away their handmade textiles and want to 'do something' about it.

For me, I was never too bothered about other people's prices. I had enough confidence in my work that I asked what I asked and if others were selling tea towels for less than I was, it wasn't a big deal to me. A few times my presence in a sale meant that those people selling for less became aware that there WAS a market for higher priced items, and in one instance, by the time I stopped doing a sale everyone else who had been charging much less then me when I first went there, were, in some cases, charging more than me. And selling. I suppose they watched my higher priced items sell and they gained the confidence to raise their prices to match - and exceed - mine.

As for those who didn't raise their prices? The people who bought the lower priced items were not 'my' customers, so I never worried about them.

Stay tuned for more information on the new book, coming down the pipeline. And yes, the hours, days, weeks involved in creating a book have a similar investment of time, knowledge, and effort.

Sunday, January 21, 2024

Repetitive

And here I go again...

I started threading yesterday and got about halfway before stopping for the day. Pushing my back into fits doesn't help anything so despite my wanting very much to get this warp up and weaving, I have to pay attention to my body. I'm still trying to figure out what causes a pain flare, and where my limit actually is.

Softly, softly, as they say.

Weaving is filled with numerous stages, all of them with (sometimes) hundreds of repetitions. For example the current warp has 760 heddles that need to be filled, in order. The posture for threading isn't great and since my hips seized up on me just over a year ago, threading has been particularly uncomfortable. Instead of threading all day and getting that task over and done with, I have had to exercise great 'patience' and spread the job out over at least two days. Since I'm meeting with someone about the fate of my large wall piece Water Sparkling Falls, today, the threading will spill over into a third day. Not a bad thing, tbh, given the pain flare I had after beaming this warp. :(

Many people have no idea of what they are getting into when they take up weaving. The creation of textiles is so far removed from daily life in the 21st century that the process is a complete mystery to most people. So when they find out about all the things that need to happen before they ever lay in a single weft, many despair of ever getting anything made.

I routinely told my students that weaving isn't difficult, but it IS complicated. All those steps required, preferably in order before the 'fun' can begin.

Some people start weaving on a rigid heddle loom where the process is less onerous. Rigid heddle looms have less mechanical assistance (shafts, treadles) and when a weaver wants to start weaving on a floor loom, they get surprised by how much the process changes. It's a lot more complicated in comparison.

When I began weaving, I had an idea of the process after receiving a weekly weaving tutorial for months. What I saw did not deter me. Instead I became intrigued with the potential. The vastness of the craft was a bit daunting, but the physicality, the mental processes involved in designing, and the creativity once I understood the processes of interweaving warp and weft appealed to me.

I accepted that the process was involved and at times complex and took that as a challenge to learn how to do it as efficiently as possible.

No warp, no weaving. I was willing - and able - and enjoyed the learning. Once I refined my techniques, weaving became a working meditation.

The fact that I am now being forced to cut back, reduce my time in the studio, is disappointing. But the fact remains - I still enjoy it, even when I know I'm going to 'pay' for it later. The challenge now is to find out where my boundaries are. How much I can safely do before setting off the pain payback.

I hosted a well known weaver when they came through on a teaching tour. At the time I was dealing with the results of an untreated whiplash injury I sustained when I was 18 and I told her that I had an 8 am physio appointment, showed her where the coffee and breakfast makings were and invited her to make herself at 'home' while I was out.

She asked if I had a back problem and I said yes. She snorted and said "All weavers have bad backs."

It was not what I wanted to hear, frankly. Especially since I had entered weaving with an historic injury that was causing problems for my weaving.

A few years later I was talking to another well known weaver who had physical issues (wore a leg brace) and I commented that it was really hard to get to the loom when I was in so much pain. They essentially said that everyone had pain and I needed do what was necessary in spite of it.

And so I did.

Most of my physical issues were not caused by weaving, but were not helped by weaving. My aim now is to work out how much I can do, and keep doing.

Because I still love to take threads and make cloth. I still have ideas for new designs and the only way to know if they will work is to weave them and then wet finish them.

I just have to find a new 'balance' of weaving and not hurting myself even more in the process.

I am fortunate in having a health care team who understand that weaving is not 'just' a physical activity that is causing me physical issues, but so much more than that.

So while I would rather be at the loom threading this warp, I will take care of 'business' and see if I can find a home for a large art piece that I would love to be on display somewhere. And give my body a 'break' from threading and finish that tomorrow.

Because those yarns aren't going to weave themselves. And they certainly are not going to thread themselves!

(current design has 1300+ picks in each towel - my towels range from 1100 to 1400 hundred picks, depending on the motif/design and thread size.)

Saturday, January 20, 2024

Creative Chaos

This past week I spent some time locating the various bins and boxes of bobbin lace 'stuff', then emptying and sorting the 'stuff'.

The goal is to offer private lessons to anyone interested, and be able to sell them a beginner's kit to get them going, if they decide they want to continue.

In the meantime, the guild has been asked if we want to do a group tree for the Festival of the Trees in November, and I realized that my plan to dig my lace stuff out and make small 'ornaments' could fit right in with this project.

I work best to a 'deadline' and this is the perfect opportunity to actually clear the dining room table of the puzzle board and set out a lace pillow. I *think* I still remember the basics of Torchon, but if I'm going to teach it would be a really good idea to make sure that I do actually still have the skills!

So I spent several hours going through everything, sorting out the bobbins I'm willing to sell, then searching online for prices of supplies.

This morning I talked to the guild person who organizes the small 'lessons' for the guild and it looks like the last two Saturdays of February are available for me to use the guild room, so now I have a more immediate deadline to refresh myself on Torchon basics.

I have four lace pillows I could sell, one of them a roller pillow, which I know I won't use. I told Doug the other day I really don't want to commit to doing a large project like a (long) piece of lace trim. But I have lots of books with small 'ornaments' which could be used for beginners to learn from, and if they decide they want to participate in making an ornament or two for the tree, well, the more the merrier!

Friday, January 19, 2024

Sectional Beaming

As usual, there are so many subtleties in weaving that one SOS student needed to see how the beginning of the warp would look like. I thought it might prove more helpful to see the end of the warp in order that they could see how the sections were all consistently lined up.

The leader strings I use are seine twine. Seine twine was engineered to be used to make seine nets (hence the name), and as such the yarn is very dense and very strong. Weavers use it for rug warps and other tasks. Before TexSolv heddles and cord were developed, seine twine was used for many of the loom cords/tie ups. Some still use it because it's a lot cheaper than TexSolv.

As it happened I had a spool of seine twine when I got my AVL because I'd been making rag rugs, so the AVL got kitted out with seine twine leader cords. When I 'retired' the AVL I kept all the leader strings and in fact, most of the leader strings on the Megado are re-used strings from the AVL. I had to change the length, but that was a simple matter of tying the loop so that it was shorter and the knot fit within the space between the rakes, but was still long enough to reach up over the back beam.

The warp gets beamed one section at a time. I have one inch sections because I knew when I bought the loom that I needed the smaller option due to my using fairly fine threads for warp. As it is, I have done projects that required 72 ends per section, although that was not common. I did do 60 and 48 epi more frequently, though, so having a studio bobbin rack that held 60 spools meant I could easily beam my finer thread warps.

My current series is 32 epi, which is what the photo shows.

The warp is not a solid colour. It is made up of equal parts peacock and bleu moyen (from Brassard). The two colours are the same value, so they don't announce themselves as being very different. However, when woven, they do show up as a subtle difference.

These are the towels that I cut off the loom a few days ago and wet finished. The colour difference doesn't show up much in the photo, although you can just see some 'streaks' happening. Those are the two different colours showing up. With one colour slightly different than the other, when I used a periwinkle blue for weft (right towel) the warp shifted to the blue end of the spectrum. When I used navy blue (left towel) for weft, the warp shifted to the green end.

Overall I have had a lot of fun working through this series, but once these colours are used up (a total of 5 warps) I will be changing to something else. Likely shawls, so I can have some available for the fall craft fair. Maybe. We'll see. That's the goal. Without goals with a deadline, I tend to procrastinate, so I'm announcing it here to remind myself what my plan is.

Always keeping in mind "The best laid schemes o' mice an' men / Gang aft a-gley.”... A fitting quote considering Robbie Burns day is coming up?

Thursday, January 18, 2024

To Write a Book

This morning I saw a post on Facebook from an author holding a copy of a book they wrote in a bookstore with an expression of delight/amazement as they held their actual real book in their hands in a real, actual bookstore.

And I thought about the road I chose, which was to be a maverick, an outlier, an 'independent' author, self-publishing their own book.

Back in the day, an author who couldn't find a 'real' publisher could purchase printed books and sell them, all by themselves. These books were called 'vanity' books and many looked down their noses because the writer didn't write well enough to interest a 'real' publisher.

When it came to Magic in the Water, though, a 'real' publisher wouldn't have touched it with a 30 foot barge pole due to the high production costs, tipping in all those samples.

I also knew the market for Magic was miniscule. So I went it alone, acted as author, editor (mostly, with some help), financier, marketing department, shipping department, loans manager, etm.

Do I regret it? No. And if anyone assumes I did it as an act of 'vanity' well, ok, I will wear that label.

But mostly I did it because I felt it was important to get the information 'out there' and the only way to do it was to provide actual fabric examples of the before and after wet finishing.

By the time I wrote The Intentional Weaver, the 'vanity' presses were now 'print on demand' operations. I was still writing, editing (with the help of a professional editor this time), marketing and shipping department for the pre-publication books I ordered in. I expected more interest in this book than Magic, and have been satisfied with the long tail income from the slow but more-or-less steady trickle of orders. So when I did Stories from the Matrix, I went the same route. My expectations for this book were lower, and that has proved to be an accurate assessment. It's not a 'textbook' and not everyone is interested in the weaving rabbit warrens I wanted to explore.

Now with A Thread Runs Through It, I expect that title to have even less appeal. It's a memoir, the story of me as a professional/production weaver. Very few people actually want to try to earn an income from their weaving - and that is perfectly understandable.

Because it's bloody hard work.

But because I've chosen to self-publish, I won't ever have the delight of seeing my book on the shelves on an actual 'real' bookstore.

If you want to make my day - a photo of any of my books in your studio (or in YOUR hands) would be lovely. :)

All books available at blurb

Two signed copies of Stories still available at my ko-fi shop

Wednesday, January 17, 2024

Some Sunny Day

Coming down to the 'end' of the current spate of tea towels, and this one is showing some promise. I'm going to tweak the treadling, I think, see if I can 'counter change' (checker board) the motifs. But even if I can't, I think I'll weave this, just to see how it turns out.

After a small snow dump yesterday (about 8" or 20 cm) we woke to a brilliant sunny day today. It's still 'cold', but a 'normal' temperature, not the extreme cold we had over the weekend. Still, I'm just as glad I don't have to leave the house.

My goal today is to finish the warp currently on the loom. I am also in the midst of sorting through my bobbin lace supplies. I have decided to downsize my bobbin lace 'stash', in part because I truly do not need that many pillows. I will keep two - my two 'favourite' pillows, and try to sell the rest.

I'm still sorting through my bobbins, but there are plenty to make beginner 'kits' - pillow with x number of bobbins. IF I can find anyone local who is interested in learning.

I also have someone who will look at the large wall piece Water Sparkling Falls, and I *may* have a 'home' for it. If not, I'm not sure what to do with it. In the end, it's just cloth, but cloth woven for a very specific purpose and not really suitable for anything else. Unless I can find another artist who might see potential in it for...something. TBD.

Sorting through the bobbin lace stuff has been a lot more emotional than I hoped. The vast majority of my bobbins were made by a friend, who died in 2018. Many of them are personalized for me - in celebration of my birthday, and such. Her husband turned the bobbins, then she painted them with things like the provincial flowers, or for xmas, easter, and such.

I found the book I wanted to use to make small birds, which I'll include in my xmas cards this year - or donate to the guild to sell. I also 'found' the card blanks with cut outs and envelopes to fit the tri-fold card stock. I did a bunch of these little birds a long time ago and included them in my xmas cards that year. What I do not want to do is begin a big lace project. So I will do smaller items, maybe put hanging threads on them so they can be hung on an xmas tree or dangle in a window. Small indulgences.

We all need a little 'pretty' in our lives. With a small amount of effort, some work with a creaky brain, and a little bit of thread, I could make some small pretties to give to my friends. One nice thing about bobbin lace is that it's pretty flexible and if you go 'wrong' sometimes it's really hard to tell. And if it can't be fixed, well its a few pennies of thread to toss. And goodness knows, I have thread aplenty, given I kept all my mom's quilting thread.

I have also promised myself I am going to tackle the loom's little quirk of tossing heddles off the end of some of the shafts. I've tried a variety of things and none of them stop it from happening. So I checked the loom and I *think* I can add a 'keeper' string, like is used on Scandinavian loom style shafts. It's a simple 'fix' and if it works, it will be a relief. I may be the only person on the planet to have a Megado that keeps tossing heddles off the ends of the shafts, but TexSolv heddles are expensive and I'm tired of tossing heddle bits away. Because the only solution is to cut them off once they fall off and become entangled. I have some 'extra' heddles I can add to one of the shafts that needed me to tie in 'repair' heddles in order to weave the current warp, but I don't have enough for all of the 3 shafts that are low (because they keep tossing their heddles off!) So I may have to buy more. But I can add some to the one that is lowest, and tie the keeper string onto the top of the shaft and see if that works. If it does, I may invest in two more bundles and add those to the two other shafts low on heddles. And then do ALL of the shafts, just because I'm tired of getting the loom all set up and then, when I go to start weaving, oops, the loom has a big mess out of sight and I need to cut the tangled heddles off before I can continue.

The problem is, tying those strings to the shafts is fiddly and awkward. So I will likely do the worst offenders to begin with, and then maybe one or two at a time until all the shafts (16) are done. I don't have a lot of tolerance for doing fiddly jobs in awkward positions.

Anyway, the sun today is very welcome. As is the snow that fell yesterday, even though the roads are crappy. We desperately need the moisture.

Tuesday, January 16, 2024

Snow!

My town sits on the confluence of two rivers and not too far away from where I live is a slough which is a protected wetlands area. It has beaver and muskrats, ducks and other wildfowl. It is a popular place to go walking.

Right now we are in the midst of a snow 'storm'. The prediction is for about 8" of snow before it stops, then more to come later in the week.

The roads are a mess, and I'm grateful I don't have to be on the highways. I do have to go to town today, although I may only go to my appointment and directly home again. Not sure I want to do errands before the snow clearing crews have had a chance to clean the streets.

I grew up in this town, and am very familiar with living with these conditions. I have the highest respect for the danger of cold weather, especially extreme cold weather. You won't find me out and about without appropriate clothing. (Coldest temps I have experienced were -50 C. I nearly had frost bite and probably on the verge of hypothermia. It was not 'fun'.)

But I am 'priviledged' insofar as I *have* cold weather gear. And the fact that I am 'retired' and can choose to not be out in this weather - if I don't have to be.

I started weaving again yesterday, having accomplished *most* of my light duty tasks on my list (and a couple that weren't!) I still have to deal with the ISBN requirements for Stories from the Matrix. I won't be applying for an ISBN for A Thread Runs Through It. Too tiny a market to bother with.

With all the changes happening in publishing and creative endeavours, I'd like to recommend to people that if they create things, they consider what will happen after their death. (Morbid? Not really - none of us gets out of here alive.) With the rise of the plagiarism machines and copyright infringements, it is a good idea to know your rights.

I have asked someone to take over my books on blurb. I have another person who says they are willing to help Doug with my studio stuff (if I go first). I have a will, although I need to make a change to a beneficiary. I have the forms, it's another thing on my radar, but waiting for something to occur so that I don't have to change it again after the something happens.

In the meantime, I continue to pick away at my stash. I feel like I've been saying this for decades: I want to weave down my yarn stash. Finally, I am beginning to feel like I have made actual headway on that. It's been 4 years since I 'retired' and only now am I beginning to see the progress I've made on weaving up my yarn.

There are two more towels to weave on the current warp, and then the loom will get dressed with the next in the series. The next warp will be a sort of 'snake skin' design. With the colours I'll be using, I'm calling it 'chameleon'. After that? A variation on the tile design I'm currently working on.

At some point I want to weave up some of the linen I 'discovered' when I cleaned out the store room for the new hvac. The humidors will be used because we are currently running about 30-35% relative humidity. And linen just behaves SO much better when it has some moisture in it. I have several tubes of a fine singles linen that I know will make wonderful tea towels. Most of the rest is thicker, so I may set up a 2/8 cotton warp to weave those yarns into. TBD.

In the meantime, I will be back to weaving because it doesn't seem to matter if I weave or not, and how much pain I have. Might as well end the day with some weaving done. And some endorphins generated via the physical activity?

I have one more bin of the dark navy towels to press, and then I'll hope for some sunshine and see if I can get decent photos of them. Then post to ko-fi with the rest.

Monday, January 15, 2024

Moving Along

This photo hasn't been seen much, in part because it isn't a great photo. But the deep dive I have been doing into my photo files means I've been 'discovering' old photos and thought I would share this one.

As part of writing A Thread Runs Through It, I spent a lot of time remembering personal projects I've done. This photo shows a double whammy.

Doug is wearing a jacket woven from 2/60 silk and alpaca, tailored by a professional tailor in Vancouver. Even though we didn't have a lot of money in those days, the fabric was too 'special' for it to be put into the hands of someone who didn't know how to properly sew it. As it happens, the tailor also provided another lesson in the value of a good HARD press. Even though I'd had it pressed by the presser at the local dry cleaner we used, the tailor spent hours giving it an even harder press before he ever contemplated cutting into it. In the end, the custom fit jacket was a 'perfect' fit, and to be honest, it still hangs in the closet where Doug will pull it out when he needs to be 'dressed up'. (It's a bit tight now, but at least he CAN wear it - can't say the same for the suit I'm wearing.)

My suit is also 2/60 silk warp and tabby weft, with a slightly textured silk pattern weft for the jacket and the blouse front. The trousers and rest of the blouse is all smooth silk.

Here's a closer look at the suit:

Doug wore his jacket to Convergence in San Jose and unless he told people it was handwoven, most people at the conference didn't realize it.

Another jacket I did was this one:

The fabric is 2/8 cotton for both layers (yes, it's stitched double weave) with a fine silk slub for the weft.

I ran out of fabric and had to quickly weave enough cloth for the sleeves, which were a heavier weight than I would have liked, but I was under an extremely tight deadline and had to work from my stash. This jacket was entered into the informal fashion show at Convergence in 1986, and at least one very experienced weaver found the cloth intriguing.

As I work my way through my memories, I am becoming aware that I really need to do...something...with the clothing I can no longer wear. I've held onto a closet full of garments, thinking that one day I would lose enough weight to wear them again. OTOH, with covid and me still avoiding the plague, I don't go to large indoor events anymore, and my handwoven clothing is too 'fancy' for my lifestyle (if you can call it such) now.

I suppose I could see if a local consignment shop would take them. Or I can leave them for my executrix to deal with...

Today I am going to try weaving again. It seems it doesn't matter if I weave or not in regards to my pain levels, so I figure I might as well end the day having done *some* weaving if I'm going to hurt anyway.

Sunday, January 14, 2024

The End

Well, I just hit 'send' on the final file for the new book.

I submit this manuscript to the editor with a great deal of trepidation, not because of what they will say, but if it will be received by the 'public' in the spirit in which it was written.

A Thread Runs Through It will be the most personal book yet, as I examine how being a professional production weaver affected me. How it changed me. How it challenged me. I have also included a lot more personal information than in my previous books, which were, frankly, more textbook than anything else. Stories from the Matrix included more personal information than the other two, but this one is more memoir than textbook.

Recently I read a comment that said something to the effect that boomers needed to stop giving advice to younger generations because society has changed so radically that any advice I might give about being a professional production weaver would be antiquated. (That wasn't what the comment said - this was me extrapolating from their example to one that applied to me.)

I had already figured that out, but felt that my growth as a human being through the lens of my career might still prove of some value to a younger person.

Because change one thing, and everything can change.

What changed in my lifetime is the rise of the internet and social media; therefore marketing has changed so radically that my experience is not relevant to someone just starting out now.

But human beings are still human beings, and the lessons I learned about being a human doing weaving for an income might be of interest to youngsters.

I don't think we have settled on a cover photo yet. OTOH, I've just sent a large fistful of photos and my editor may decide to take one of those - or ask for me to send something current. TBD.

My 'light duty' days are nearly over. I will try weaving tomorrow and see how it goes. Tuesday I have chiropractor and won't likely feel much like weaving. I do still have a couple more administrivia tasks to be done, so I will sort through the heap of paper on my desk and hopefully deal with the rest after my appointment. It would be great to begin digging into the next warp (once the current one is off the loom) with a clean slate on my desk.

Who knows, my 'muse' may begin poking me again. She seems content - for now. But who knows. I never intended to write a second book, never mind a third - or fourth.

Go with the flow, they said. It will be fun, they said. Riiiiiight....

Tentative publication date is Feb. 14. Because this book is a long song to weaving, so to speak.

Saturday, January 13, 2024

Perceptions (CW warning - wokeness alert)

This is not a 'great' photo, but I was going for accuracy of colour, not 'eye candy'. To that end, I got pretty close. The warp is Peacock and Bleu Moyen from Brassard, and the weft on the left is navy while the weft on the right is a kind of periwinkle blue. The warp is the same for both, but the weft colour is shifting our perception of what we see. And the camera interprets what it 'sees' which may or may not, reflect what my eye sees.

And so it is with Life. Our perceptions can 'fool' us into seeing something that isn't accurate.

As I get older, my lifetime of experiences has given me a certain perception of what has happened. But I have to remember that all of my perceptions are filtered through my reality bubble.

What is that? What seems 'normal' to me, may be vastly different to someone else, even as they experience the same event.

Or as they say, we are not all in the same boat, we are in the same storm. Some of us may have a yacht, some of us may have a rickety boat, some of us may have a raft. And not all of us may have a life jacket.

So that storm may look very different depending on where you are standing. Or floating.

Every once in a while I get yanked out of my reality bubble by someone who has a different set of experiences forming *their* reality bubble. Sometimes it is a gentle suggestion that I re-think my attitude. Sometimes it is not-so-gentle.

It is never comfortable to be reminded that others have different experiences, different realities, that make my life look very different from theirs.

It may be a desire to defend myself that I need to overcome, when the appropriate response is to be quiet, think before I speak, and open my heart and mind to hear what the other person is really saying.

I think the first time I really understood this was reading a book called Black Like Me.

It shook me to my core, to be honest. In the small town I lived in there was, at the time I read it, exactly one black person living here. But we had tv and I could see what was happening on the news - the whole desegregation struggles going on. It became more 'personal' when I learned about the experience of black people in Canada. We were not the shining light of equality I had been led to believe. And then I learned about the Indian Act, and the way Europeans treated the indigenous peoples, up to and including the 'residential schools' that still existed, well into the 1990s.

As a young adult I became aware of the work Brigette Moran was doing with First Nations people who lived in and around my town, and the vitriol of a segment of the population about her advocacy of rights for the people living under a cloud of racism.

As I read more, learned more (Bury My Heart at Wounded Knee, etc) I had to get over, through, around, my reality bubble that said such things did not exist. I had to learn that just because they did not happen to me, didn't mean they didn't happen to others.

Then I saw a documentary about the Blue Eyes, Brown Eyes experiment by Jane Elliot.

As I learned more, I *saw* more. I could no longer deny the attitudes I could see at play around me, even when they did not apply to me.

Living is a constant state of new experiences. Learning more. Changing attitudes. And still getting tripped up by my reality bubble/perceptions - what is 'real' and what is just my perception of 'real'.

I have benefited from people who have called me out when I said something that was judgmental, biased, closed minded. Those times have never been 'comfortable' as I had to stop, think, re-calculate and tear another layer off my reality bubble. I have had to set my discomfort aside, swallow hard, and change my language, my attitude.

We are all works in progress. My hope is that I never become so set in my ways, my attitudes, that I cannot change my mind. That I can continue to learn, to grow.

Weaving helps me with this journey because over and over again I learn - change one thing, and everything can change. In the photo above, the weft yarn colour is the only thing that has changed. Same warp. Same density. Same design. Different weft colours. Two different towels. Neither is 'better' than the other.

"Do the best you can until you know better. When you know better, do better." Maya Angelou

In weaving as in life. Do the best you can. But keep an open mind so that when you know better, you can do better.