Yesterday I saw a conversation online about the 'proper' epi for a particular size of yarn woven in plain weave. As usual, some people strongly urged people to use 20 epi, others strongly advocated for 16-18 epi. Most people were calling it 8/2, so I could only assume that they were using and talking about US 8/2 cotton, not Brassard's 2/8. (In the photo above, the rust yarn is Brassard's 2/16; the teal is US 16/2 cotton.)

Why do I call Brassard's 2/8 instead of 8/2? Is it merely because I'm Canadian and 'contrary'?

Not entirely. (Although I freely admit to being 'contrary' at times!)

It is *because* I am Canadian and the first cotton yarns that I was introduced to were the 2/8 cottons from Brassard, South Landing and Curl Brothers, long before I was introduced to US 8/2 cotton. At the time I had been very confused at how many USians would turn their noses up at 2/8 (or as they said, 8/2) cotton.

Once I was able to see the yarns, side by side (in my own mind, if no where else), I came to understand why the USians preferred other yarns - all those lovely mercerized yarns which were spun ring spun, and then treated to have that sheen so typical of mercerized yarns.

Many USian weavers also referred to 'Perle' (or Purl) cottons as if they were a 'type' and all exactly the same. (For example, check out Astra mercerized cottons compared to other mercerized yarns - they are not the same, either.)

It is why, when I answer a question, I will inevitably begin by saying 'It depends.'

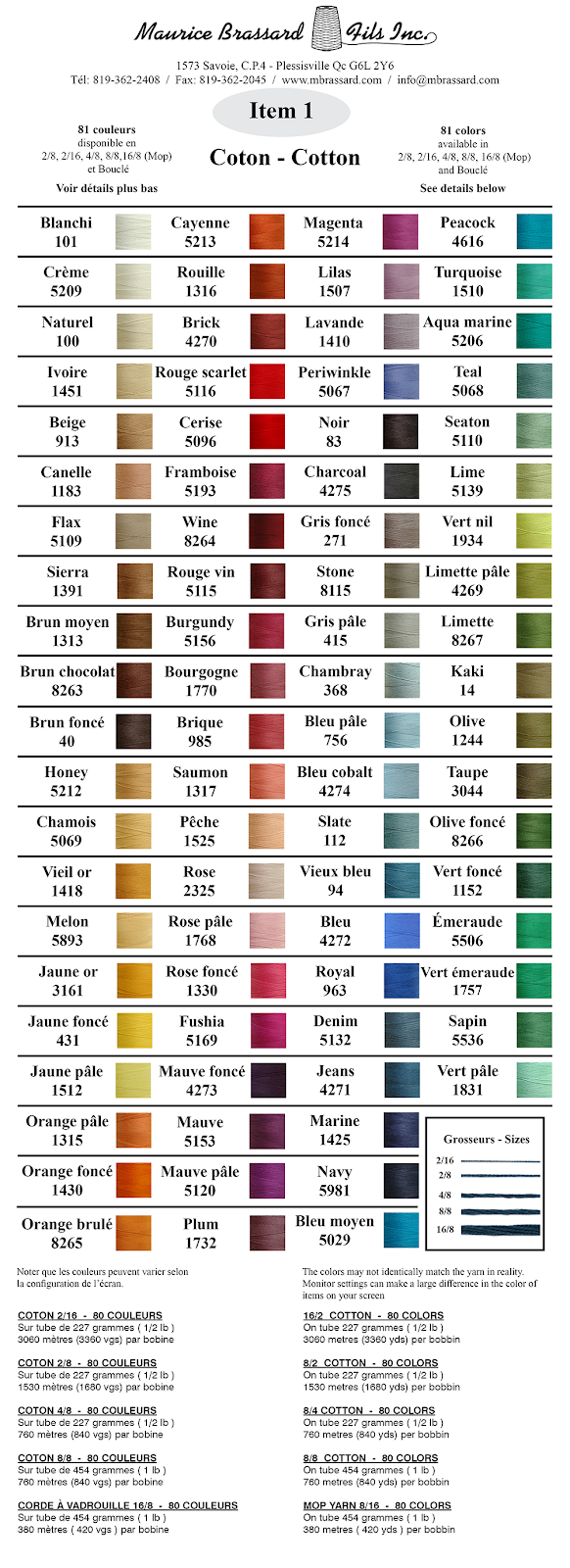

That US spun 8/2 cotton is NOT the same quality as the 2/8 cotton (usually called 8/2 now, but if you look at the Brassard website on the French page, they *still* call it 2/8.)

I know you probably can't see it on this tiny image of their colour card, put it's still there, 2/8, just like when I started weaving back in 1975.

The thing is, open end spun and ring spun yarn are not identical to each other. They have different natures/characteristics. (If you are a long time reader of this blog, this is a repeat for you - but I've had some new readers join since getting involved with BlueSky.)

I've written about this elsewhere and here, else when. As a weaver, one of the things that helps to know is the nature of your materials. If you don't understand their nature, it's a lot more difficult to chose the various things that have to be decided on as you go through the design processes. (More info on this in Stories From the Matrix and The Intentional Weaver.)

I am, right this time, sampling for an article I am going to be submitting to WEFT magazine. My first sample turned out for one weft, not so well for the second one. My decision to try again was set in concrete when I realized (belatedly) that I'd made a tie up mistake when I designed the 2nd option.

I anticipated that I would need a second warp to test a different epi based on the very different natures of the two wefts, so when I discovered that I did, indeed, need to set up a second warp to test the lower epi, I wasn't particularly upset. It was Plan B all along.

Given the hours it may take to design a new warp, there is a reason I want to set the loom up to weave quite a lot of it. The design hours get 'amortized' over a larger number of finished items.

As for the balance of this first, tentative warp, it is being woven off as tea towels, using the 2/16 cotton weft. They have great drape, which is desired in a tea towel. They will likely be listed in my ko-fi shop late December or early next year. I do still have to weave, wet finish, and hem them, after all.

Doesn't matter how 'efficient' you may be, you are still weaving 'slow' cloth...

No comments:

Post a Comment