The more things change, the more they stay the same.

Kind of sums up things, really.

I've been weaving a rather long time. From the 1980s to 2019, I wove on an AVL, which was a very particular kind of loom. When I got the Megado, I had to change the way I dealt with how I threaded the loom, mainly what I did with my threading draft. I happened to have an old typist's clipboard, meant to hold things as the typist typed the information. It might be typing them onto letterhead, or a stencil. (Yes, I'm *that* old!)

I bought one, but didn't like it at the desktop because it didn't fit well in the limited space beside the cpu and the monitor, and when I started setting up the Megado, I had to find a different way to handle the printed out drafts. For the longest time (late 2019 until, well, now) I had placed the clipboard onto the laptop on the table next to the loom.

But as my back got worse, twisting from sitting forward at the loom to thread, to checking the draft for the next combination of threads and marking off the ones just threaded, began to irritate me.

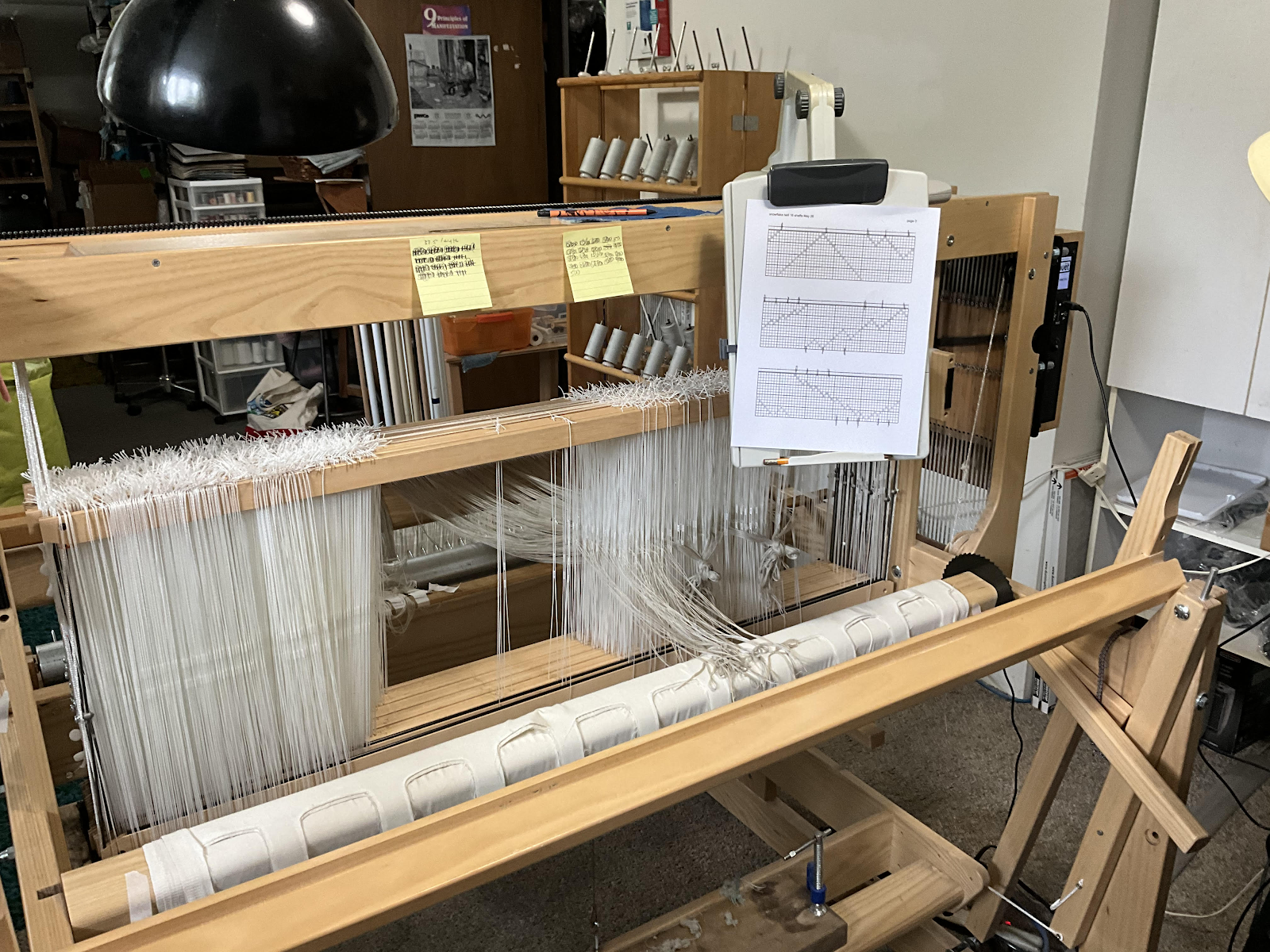

On the last warp I took a look around and realized that the Megado had a 'hard top', which I understand some people use to place their ipads or laptops to run the dobby. I don't like the prospect of setting an expensive electronic device on top of the loom, that slightly jiggles and generally is not exactly 'stable' like my table is. However, I'm not weaving right now, and hmm - would the base of the clipboard 'fit' on the top of the loom?

I adjusted it to tailor it to my needs, and in the end? I'm finding it much easier. I don't know if it will reduce the wear and tear on my back, but it feels 'better', so hopefully.

I print out the entire draft, which tends to take 5-7 pages of paper. As I thread each bout of ends, I mark them off on the draft so that I know I've done that bundle. As I thread them, I tie a slip knot in each group, and then when I've done a repeat, I loosely slip knot that, too.

The bottom part of the shaft is a narrow piece of wood, which I can just write on with a pencil so that each shaft is numbered 1-16. Fiberworks prints drafts out with the number of each shaft that is being used. For a group of numbers (13-16 for example) I have the numbers on the shafts to identify which shafts I need in the group. It's a number to number correlation. Which makes more sense to me than to have the draft in numbers and the heddles a rainbow of colours.

But we each have to work out what processes are 'best' for ourselves. Personally I find a rainbow of colours in the heddles distracting, not helpful, but we all process information in different ways, so try a few things and figure what is best practice for you!

No comments:

Post a Comment